Menu

Our Coatings

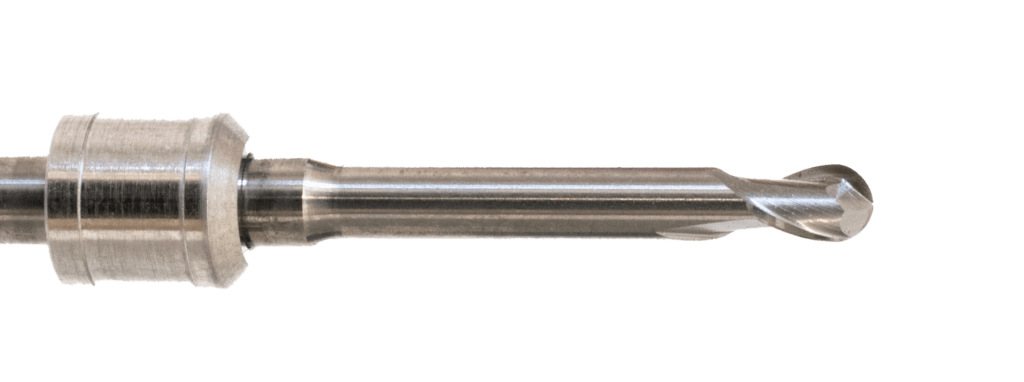

Uncoated

All our milling burs are produced from premium Tungsten Carbide. A specialized grinding process is used to achieve a highly polished finish on the milling bur flutes, resulting in improved chip flow during milling.

Uncoated milling burs are ideal for machining PMMA, wax, PEEK.

Real Diamond Coating

The CVD multi-layer diamond coating provides outstanding performance, making it particularly suitable for machining highly abrasive materials such as zirconium oxide (zirconia). Diamond-coated tools last several times longer than their non-coated counterp arts, resulting in a significant difference in durability.

Characteristics:

Color: Black

Hardness (HV 0,05): 10,000

Titanium Silicon Nitride (TiSiN)

A PVD multi-layer coating known for its low adhesion properties. This coating enables operation at high temperatures of up to 1100°C, making it ideal for machining metals such as Titanium and Cobalt Chrome.

Characteristics:

Color: Copper

Hardness (HV 0,05): 4,000

*Additional types of coatings are available according to specific requirements.